Aluminum Foundry is preferred for reliability in aluminum casting processes

Wiki Article

Recognizing the Various Sorts Of Processes in An Aluminum Foundry for Effective Production

In An Aluminum Foundry, various casting procedures play a crucial role in manufacturing efficiency. Each approach, from sand casting to die spreading, uses unique benefits that deal with specific manufacturing requirements. Understanding these procedures is essential for maximizing quality and price. Nonetheless, the selection of casting method can significantly affect overall outcome. As factories explore these alternatives, they must think about which approaches straighten finest with their production objectives. What aspects will ultimately lead their choices?Summary of Aluminum Foundry Processes

Aluminum Foundry procedures encompass a collection of specialized techniques aimed at changing raw Aluminum right into usable elements. These processes generally start with thawing the Aluminum, where key or scrap Aluminum is heated up until it reaches a liquified state. Once thawed, the Aluminum might go through alloying, where details aspects are added to improve its residential or commercial properties, such as strength or deterioration resistance.Adhering to melting and alloying, the Aluminum is put right into mold and mildews to create wanted forms. Air conditioning and solidification happen, during which the product handles the type of the mold. After solidification, castings are gotten rid of and may require more processing, including cutting, machining, or surface therapy to accomplish the final requirements. Quality control is integral throughout the procedure, making sure that the produced elements meet market standards. Generally, Aluminum Foundry processes are important for generating a vast range of light-weight and durable items utilized in numerous applications.

Sand Casting Strategies

A substantial portion of Aluminum castings are generated using sand casting methods, which is a functional technique favored for its capacity to produce complicated forms. In this process, a mold is made from sand combined with a binding representative, ensuring it can withstand the liquified Aluminum's temperature. The pattern, typically made of steel or plastic, is placed in the sand to create the dental caries for the spreading. After eliminating the pattern, the mold is full of molten Aluminum, which solidifies right into the wanted shape upon air conditioning.Sand casting is particularly helpful for low to medium manufacturing volumes because of its cost-effectiveness and versatility. Additionally, it permits simple adjustments of mold designs, fitting various component geometries. Though it might not accomplish the dimensional precision of other casting methods, the surface coating can be improved via succeeding machining. Generally, sand spreading continues to be a cornerstone of Aluminum Foundry processes, making sure varied applications across markets.

Pass Away Spreading Methods

In the domain name of die spreading techniques, two primary procedures stand apart: the hot chamber and chilly chamber techniques. Each method presents special advantages and obstacles, particularly relating to effectiveness and product compatibility. Furthermore, the selection of die materials plays a necessary role in figuring out the overall success and toughness of the casting process.Warm Chamber Refine

Cold Chamber Process

Cold chamber die casting stands for an alternative approach for generating Aluminum parts, especially when managing metals that have higher melting points or when the molten steel is as well responsive for warm chamber procedures. In this method, molten Aluminum is put right into the die from an external ladle, which minimizes the threat of contamination and enables better convenience in alloy option. The procedure entails infusing the liquified steel right into a cold die using a hydraulic piston, guaranteeing specific control over the injection speed and pressure. This approach is useful for creating intricate geometries and accomplishing high dimensional precision. Although it may call for longer cycle times compared to hot chamber procedures, cool chamber die casting is crucial for particular applications in Aluminum foundries.Die Materials Choice

Choosing the proper die materials is vital for optimizing the die spreading process and guaranteeing the long life and efficiency of the molds. The most generally utilized products consist of device steel, Aluminum, and beryllium-copper alloys, each offering unique advantages. Device steel is favored for its sturdiness and resistance to use, making it excellent for high-volume manufacturing runs. Aluminum offers excellent thermal conductivity, facilitating reliable warmth dissipation, while beryllium-copper alloys integrate stamina and thermal administration buildings, however at a greater expense. Variables influencing the selection consist of the complexity of the part, anticipated production quantity, and the details Aluminum alloys being cast. Eventually, the ideal choice of die product can substantially enhance performance and minimize general functional costs in Aluminum shops.Financial Investment Casting Processes

While various casting methods exist, investment casting attracts attention for its capability to produce intricate forms with high accuracy and outstanding surface area finishes. This procedure includes producing a wax pattern that is covered with a ceramic shell. When the covering solidifies, the wax is dissolved, leaving a tooth cavity that is full of molten Aluminum.Investment spreading is particularly useful for creating intricate geometries that would certainly be impossible or tough to attain with other methods. It enables for limited tolerances, lowering the need for considerable machining post-casting. In addition, the smooth surface area coating minimizes the need for secondary procedures, therefore improving efficiency.

This method is extensively used in markets requiring thorough elements, such as aerospace and medical markets. The versatility of investment casting allows the manufacturing of both large and tiny quantities, making it an important option in Aluminum foundries looking for to fulfill varied production needs.

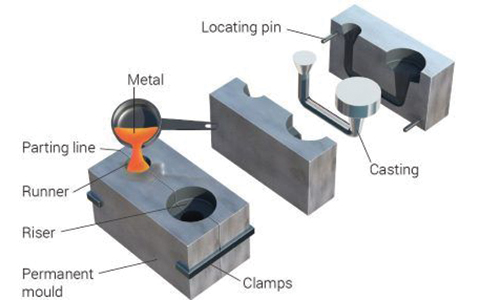

Long-term Mold Casting

Long-term mold and mildew spreading is an approach that utilizes reusable mold and mildews to create Aluminum elements, improving effectiveness in manufacturing. This technique uses numerous advantages, including enhanced dimensional accuracy and surface area finish, making it appropriate for various commercial applications. By understanding its procedure, advantages, and utilizes, one can appreciate its value in the Aluminum Foundry market.Process Overview

Aluminum Foundry procedures include numerous methods, among which is permanent mold and mildew casting. This approach uses recyclable molds, commonly made from metal, allowing for efficient production of Aluminum parts. The procedure starts with pre-heating the mold and mildew to enhance fluidity and reduce flaws. Molten Aluminum is after that poured into the mold and mildew under gravity or pressure, guaranteeing accurate filling and lessening air entrapment. Once the Aluminum cools and strengthens, the mold and mildew is opened up to fetch the cast component. Permanent mold spreading is recognized for producing premium, dimensionally accurate components appropriate for various applications. The strategy is especially beneficial for high-volume manufacturing runs, as it considerably reduces product waste and enhances repeatability in producing processes.Benefits of Strategy

Different casting approaches exist, long-term mold casting supplies distinctive advantages that make it a favored choice for many manufacturers. This technique enables premium dimensional accuracy and surface coating, minimizing the demand for substantial machining. The recyclable mold and mildews, usually made from steel, improve manufacturing performance by enabling rapid cycle times and lower general material prices. Furthermore, long-term mold and mildew casting promotes boosted mechanical homes in the final product because of the regulated cooling prices, which result in finer grain structures. Furthermore, as the process generates much less waste compared to sand spreading, it is extra eco friendly. In general, these benefits add to cost-effectiveness and high-quality end results, making long-term mold casting a critical choice in the Aluminum Foundry sector.

Applications in Industry

In numerous markets, permanent mold and mildew spreading plays a vital function in producing high-quality Aluminum components, especially where accuracy and longevity are vital - Aluminum Foundry. This technique is widely utilized in the automobile industry for manufacturing engine blocks, transmission real estates, and various other critical parts that require precise resistances and robust performance. In addition, the aerospace industry benefits from permanent mold and mildew casting for elements that should withstand extreme problems while keeping lightweight attributes. In addition, durable goods frequently utilize this strategy for creating durable and cosmetically pleasing products, such as cookware and ornamental components. The capacity to attain intricate geometries and great surface area coatings makes permanent mold casting a recommended option across varied applications, making sure effective and dependable manufacturing in various commercial contextsMachining and Finishing Operations

Accuracy machining and ending up procedures play a necessary role in the Aluminum Foundry process, making certain that cast components fulfill rigorous high quality and dimensional specifications. These operations entail various strategies, such as milling, turning, exploration, and grinding, which are utilized to improve the surface areas of actors parts. Each strategy is chosen based on the particular requirements of the part, including its size, form, and designated application.Completing processes, such as anodizing and surface area polishing, boost the aesthetic allure and deterioration resistance of Aluminum components. Additionally, these operations assist attain tighter resistances and smoother coatings, which are essential for performance in numerous industrial applications.

Top Quality Control in Aluminum Foundries

Quality control in Aluminum foundries is an essential element that guarantees the stability and performance of actors products. This process entails methodical examinations and testing at numerous stages of production. Factories apply rigorous quality checks, consisting of aesthetic assessments, dimensional measurements, and product evaluation, to establish that every cast fulfills specified criteria.Additionally, advanced methods such as non-destructive testing (NDT) are utilized to find internal defects that may not be visible on the surface. By keeping an eye on variables like temperature level and alloy composition, shops can preserve excellent production conditions, minimizing the chance of defects.

Adherence to industry standards, such as ISO accreditations, strengthens a shop's dedication to high quality. Constant training and development of personnel also play a critical function in fostering a society of high quality recognition. Eventually, efficient high quality control practices enhance client fulfillment and minimize costly rework and scrap, ensuring the Foundry's competitive side on the market.

Frequently Asked Inquiries

What Safety And Security Measures Are Needed in An Aluminum Foundry?

Safety and security measures in An Aluminum Foundry include correct personal safety equipment, ventilation systems to take care of fumes, fire avoidance procedures, regular tools maintenance, Aluminum Foundry staff member training on risks, and emergency situation action prepares to attend to prospective crashes successfully.Just How Does Recycling Aluminum Affect Foundry Processes?

Reusing Aluminum substantially impacts Foundry procedures by reducing resources prices, decreasing waste, and reducing power usage. This environmentally friendly approach improves production efficiency while advertising sustainability, inevitably profiting both the atmosphere and the Aluminum industry.What Are the Environmental Influences of Aluminum Foundries?

The ecological effects of Aluminum shops include air and water pollution, high power intake, and considerable greenhouse gas discharges. These variables add to habitat destruction and health and wellness threats for bordering areas, requiring boosted sustainability techniques.Just How Do Foundries Handle Waste and Emissions?

Foundries manage waste and exhausts with different strategies, including reusing scrap metal, carrying out filtering systems, and adhering to environmental guidelines. These procedures intend to lessen environmental influence while preserving functional efficiency and productivity.What Is the Duty of Automation in Aluminum Foundries?

Automation in Aluminum factories boosts performance and accuracy. It decreases human error, maximizes production procedures, and lowers labor prices. By incorporating innovative modern technology, factories can boost product top quality and warranty regular operational efficiency.Aluminum Foundry procedures encompass a collection of specialized techniques intended at changing raw Aluminum into usable elements. These processes commonly begin with thawing the Aluminum, where primary or scrap Aluminum is heated up until it gets to a molten state. The warm chamber procedure is a very effective die spreading approach commonly utilized for Aluminum alloys. Cold chamber pass away spreading represents an alternate method for generating Aluminum parts, specifically when dealing with steels that have greater melting factors or when the molten steel is too reactive for hot chamber procedures. Aluminum Foundry. Aluminum Foundry procedures include different techniques, one of which is permanent mold and mildew spreading

Report this wiki page